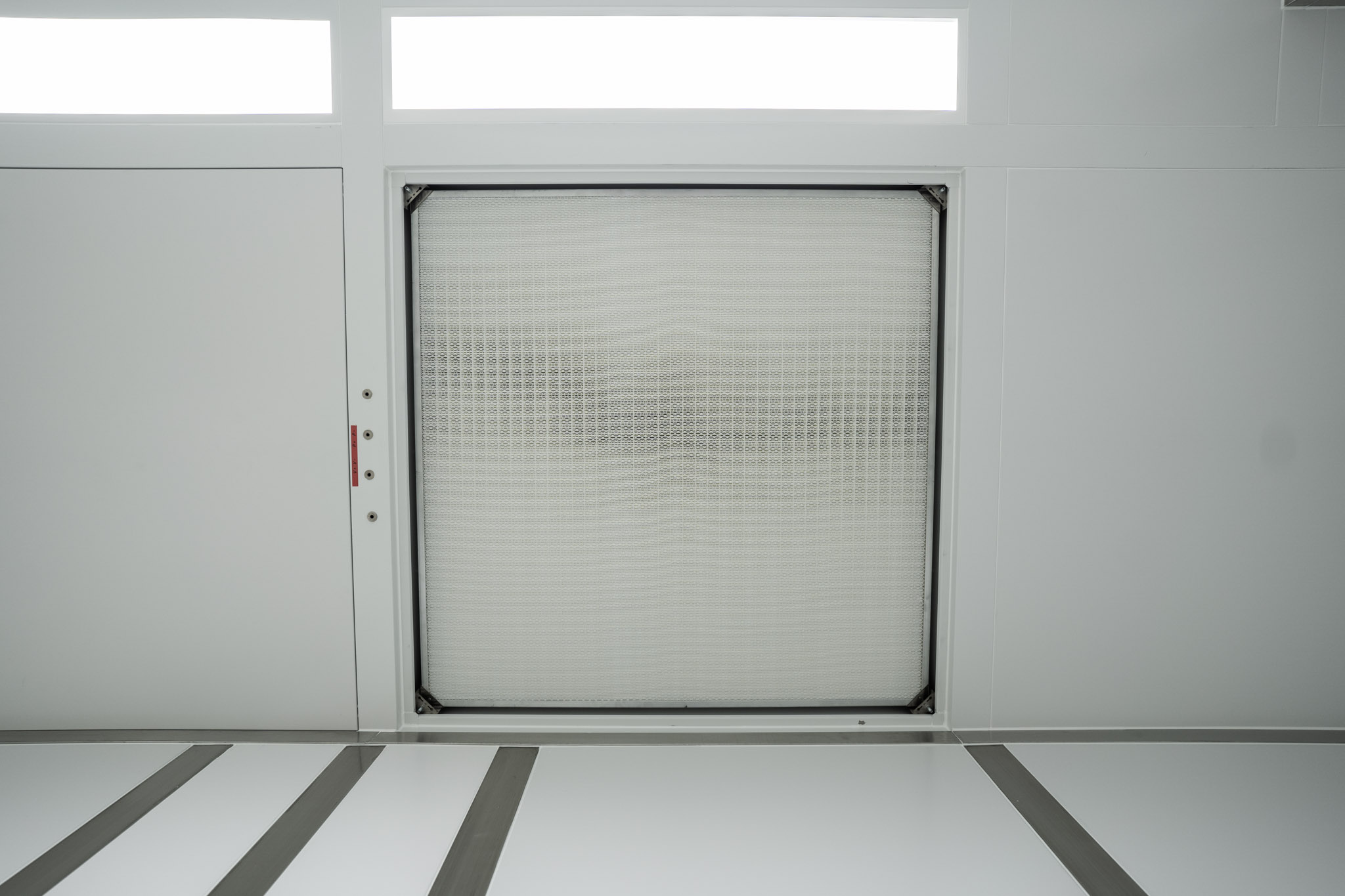

HEPA BOX / Filters

Used in supply ventilation for cleaning air from pollutants of all types of production facilities in the electronics, pharmaceutical, chemical, food industries, and in precision engineering machinery, laboratories. It is also used in exhaust ventilation systems to protect against hazardous emissions. The design is installed in the ceiling grid system as well as in wall systems.

The structure consists of prefabricated elements powder coated in RAL 9016 antistatic (standard color, can be replaced at the customer's discretion). The standard size of the structure according to the ceiling system cells is 1.2 x 1.2 meters. It is allowed to change the size, due to the impossibility of installing the standard size and in case of passing the installation according to the design parameters.

The main elements of the installation are:

> plenum above cleanroom ceiling

> Hepa-filter frame

> HEPA-filter

> diffuser / perforated grille

Ventilation plenum

The construction element is designed for air supply. The construction differs in the location of air intake (according to the project)

with different diameters of pipe ventilation connection flanges, dimensions for the required filter cross-section 400, 500, 600, 800 mm. Riveted galvanized construction with sealed joints, complete with quick-release fasteners to the frame of the Nera-filter.

HEPA-filter frame

Manufactured according to the project and for the required filter. The design is characterized by fastening elements for the required filter with cross-section of 400, 500, 600, 800 mm. Welded frame construction, complete with fastening elements for installation of Hepa-filter. Painted with antistatic powder paint in RAL 9016 or made of stainless steel AISI304.

HEPA-filter

The frame consists of an aluminum housing, equipped with a seal (gel) for a tight fit and installation in the frame, along with a protective mesh for the filtering filling. The filter replacement is carried out from inside the clean room.

Diffuser

The construction is equipped with openings with airflow adjustment elements of a defined area, for design requirements of 400, 500, 600, 800 mm. For ease of maintenance, the grille is fixed

to the installation by a system of magnets and safety leashes to prevent falling. It is painted with antistatic powder paint in RAL 9016 or made of stainless steel AISI304. Also available in perforated version ø 5 and 9 mm,

depending on the application.