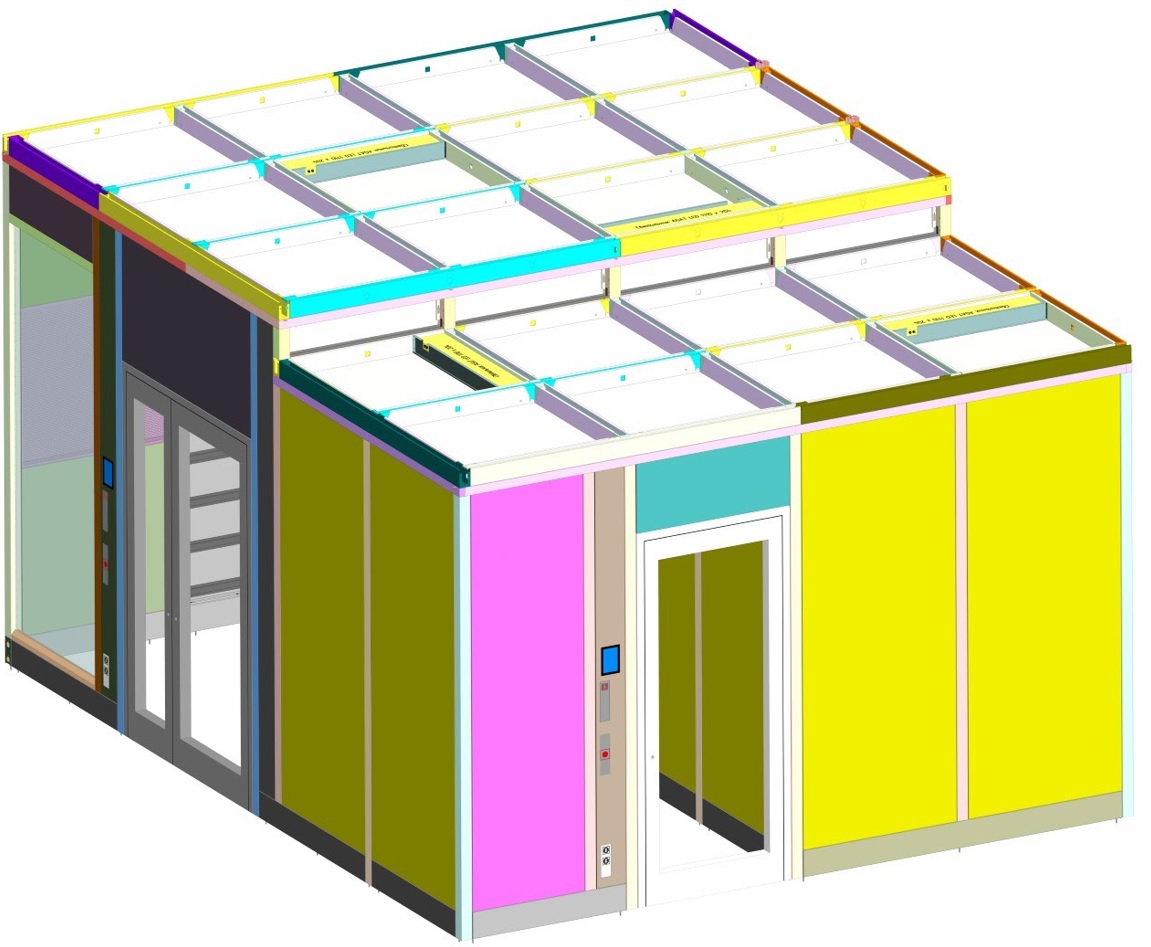

Wall and Ceiling Panels

Wall and ceiling panels.

The ceiling grid system is the load-bearing structure of Cleanrooms.

Wall system - the design allows changing the configuration of rooms or damaged panels without disassembling the ceiling.

The main element of the structure that creates a barrier to the penetration of contaminating particles into the clean area.

MatrixWall modular system allows instant disassembly and installation of wall or ceiling panels.

The main elements of the ceiling grid system:

> ceiling profile

> ceiling panel

> lighting panel

> panels for the process equipment

> ceiling cover (walkable panel)

Full height of all mounted elements of ceiling system is 120 mm.

Ceiling profile

The structure consists of galvanized sheet steel with a powder coating of RAL 9016 (standard color, can be replaced at the discretion of the customer). The standard distance in the grid between the supporting profiles is 1.2 m, the maximum distance between the supporting hangers of the ceiling profiles is 2.40 m.

Due to the box-shaped design and the embedded holes for fasteners, the entire assembled structure has a strong connection, forming a single supporting structure.

The entire system is suspended using specially formed brackets and rods to a concrete floor or supporting metal structures.

Ceiling panel

The standard size for the ceiling grid system is 1.2 x 1.2 m, it is possible to manufacture panels with the size for the required cell, consisting of galvanized sheet steel with a powder coating

RAL 9016 (standard color, can be replaced at the discretion of the customer). The coating has excellent mechanical and UV resistance.

The panels are designed for gas- and dust-proof installation

in a supporting grid structure in cells without lighting fixtures and diffusion grids.

During the reconstruction of the rooms, the panels can be easily dismantled and mounted in any cell of the ceiling grid system.

Ceiling panel with a lamp

A cutout is made in the ceiling panel for mounting lamps (at the MatrixWall production facility). The panel with the lamp includes:

-

4 mm thick tempered glass, which is glued in the MatrixWall production

-

IP40 LED lamp, which is installed, connected and serviced from the ceiling space, and not from the clean room side

-

The ceiling panel is covered from above with a walkable panel, which prevents dust and water from getting into the lamp

Ceiling covers (walkable panel)

Consisting of galvanized sheet steel. The panel is laid on the ceiling panels with a hook to the ceiling profile and pulled together with special brackets to achieve a more durable structure.

The mounted ceiling system allows for virtually unlimited installation of process equipment and movement behind the ceiling space with an allowable load of 150 kg per 1 m².

Main elements of the wall system:

> floor plinth

> column (wall support)

> wall panels

> glass panels

> U-shaped ceiling guide of the wall panel

> ceiling guide of the glass panel 10 mm

The wall system has a thickness of all mounted elements of 80 mm. In height (at the customer's request) up to 6 m.

Floor plinth

It’s standard size - height 180 mm, length up to 2.4 m, forms a connection between the wall and the finished floor level.

The structure consists of stainless steel AISI304 and galvanized steel stiffeners, forming a shock-resistant and load-bearing structure.

Installation is carried out on the floor in accordance with the room plan, fastening is carried out mechanically to the floor with an anchor screw.

Columns (wall supports)

Installed according to the project at the point of the wall grid. The usual grid is 1.2 m, but other grid sizes can be implemented. The structure consists of a profile pipe 80x80 mm. stainless steel AISI304.

Installation is carried out both on the floor and on the floor plinth, according to the load.

Depending on the requirements, various wall panels can be inserted into this frame wall structure, i.e. standard single/double-layer wall panels, glass panel, or doors. The design also allows for the installation of prefabricated walls between two columns, i.e. wall panel / glass panel, wall panel / glass panel / wall panel, of any size.

U-shaped ceiling profile

Forms a connection between the wall (wall system) and the ceiling (ceiling grid system) of a clean room.

In addition to its function as a retaining element for the wall, the ceiling profile also balances the height difference between changing ceiling loads or uneven floors. The profile is made of AISI304 stainless steel.

The individual joints of the profile always correspond to the wall grid. The standard profile length is 2400 mm. Special lengths from 240 to 3600 mm are feasible.

Wall panel

Installed flush on the floor plinth, between two columns on latches, at the top in a U-shaped ceiling profile, where the joints are calculated so that the wall surface forms a smooth surface.

Standard panel width from 240 to 1200 mm, height from 240 to 4000 mm. If the height exceeds 4000 mm, the panel is installed through a transition profile.

The structure consists of galvanized sheet steel with a powder coating RAL 9016 on the front side. For reinforcement, bent sheet steel profiles are glued to the back side of the panels.

Glass panels

Installed in the center on the floor plinth and covered with a decorative profile, between two columns, at the top in the ceiling guide profile of the glass panel. The panel is made of tempered glass 10 mm thick.

The size of the glass panel depends on the project.

-

All stitches of a Cleanroom structures (Ceiling Grid System and Wall System) are sealed with a special sealant for clean rooms

-

All materials, components, and clean room structures are certified

Installation of a Cleanroom frameworks is carried out with a minimum set of tools, without lifting equipment and in a short time.